Generation of an accessible and versatile hypoxia chamber

Project Overview

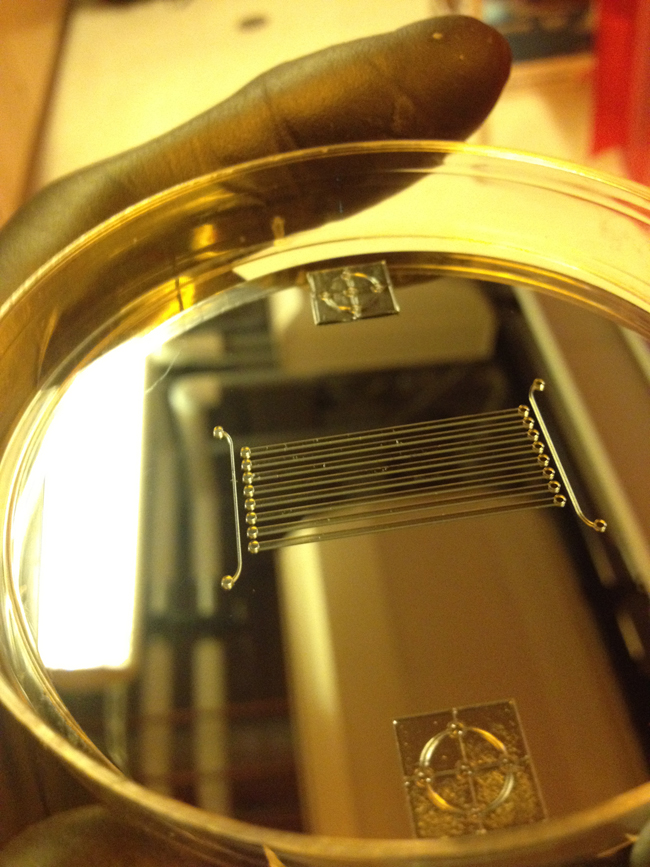

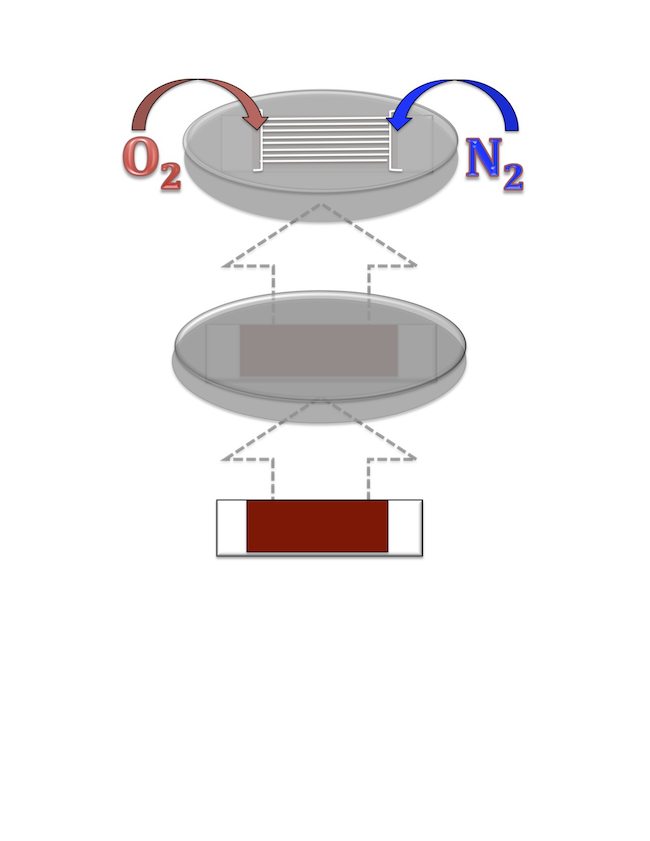

Understanding the impact of hypoxic stress on the behavior of cells transplanted to the heart following ischemic injury can be achieved by mimicking facets of the in vivo environment in an in vitro system. Control of oxygen levels in cell culture has traditionally be achieved using large hypoxia chambers at one concentration at a time. Microfluidic devices have been proposed to improve accessibility, versatility, and to generate overall function of hypoxic environments. The goal of this project is to design and produce a microfluidic-based hypoxia chamber to facilitate experimental investigations involving oxidative stress, ischemia, and reactive oxygen species (ROS)-mediate cellular pathways. Previous semester’s work on this design project produced a functioning microfluidic-based hypoxia chamber. This semester’s work will focus on developing a means to accurately monitor and detect the varying oxygen concentrations and gradients present in the chamber.

Team Picture

Images

Files

- Research Article- Optical Oxygen Sensors for Applications in Microfluidic Cell Culture (October 12, 2012)

- Hypoxia Chamber-Oxygen Detection-PDS (October 19, 2012)

- Hypoxia Chamber-Oxygen Detection-Design Matrix and Design Alternatives (October 18, 2012)

- Hypoxia Chamber-Conceptual Diagram of Final Design (December 12, 2012)

- Hypoxia Chamber - Oxygen Detection - Midsemester Presentation (October 21, 2012)

- Hypoxia Chamber-Oxygen Detection-Midsemester Paper (December 13, 2012)

- Hypoxia Chamber-Cost Analysis of Final Design (December 12, 2012)

- Hypoxia Chamber-Experimental Procedures and Protocols (December 12, 2012)

- Hypoxia Chamber-Final Poster Presentation (December 12, 2012)

- Hypoxia Chamber - Oxygen Detection - Final Report (December 12, 2012)

Contact Information

Team Members

- Matthew Zanotelli - Team Leader

- Chelsea Bledsoe - Communicator

- Karl Kabarowski - BSAC

- Evan Lange - BWIG

Advisor and Client

- Prof. Randolph Ashton - Advisor

- Prof. Brenda Ogle - Client

Related Projects

- Spring 2013: Generation of an accessible and versatile hypoxia chamber

- Fall 2012: Generation of an accessible and versatile hypoxia chamber

- Spring 2012: Generation of an accessible and versatile hypoxia chamber