Impact wrench for orthopedics

This project has been secured to protect intellectual property.

Login for More InformationProject Overview

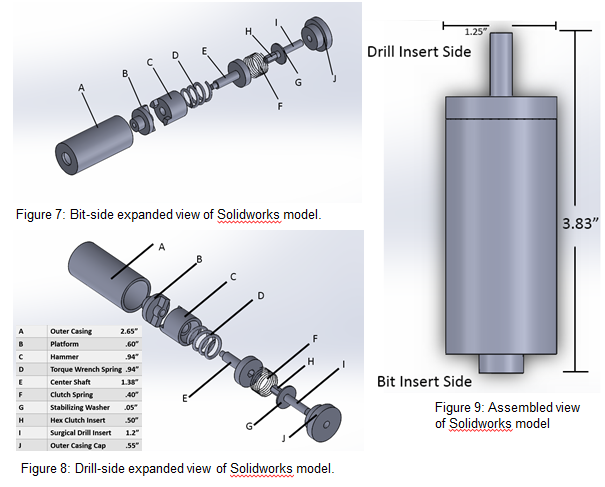

Hardware removal is a required part of orthopedic surgery, and often times screws have been implanted for over a year and are very tight at the time of removal. When a screw gets stripped, it becomes much harder to remove. Impact wrenches for automotive applications exist, but they are too large for the hardware used in orthopedics. Our client currently has a prototype, but it is too bulky to be used in orthopedics and may not output the adequate torque for removal of screws. Our goal is to design an impact wrench that is smaller than the current prototype and can still output enough torque to remove the screws and not strip them.

Team Picture

Images

Contact Information

Team Members

- Evan Jellings - Team Leader

- Joseph Ulbrich - Communicator

- Nicholas Hoppe - BSAC

- Alison Walter - BWIG

- Mr. Andy Siedschlag - BPAG

Advisor and Client

- Prof. John Puccinelli - Advisor

- Dr. John Wollaeger - Client

Related Projects

- Fall 2015: Impact wrench for orthopedics

- Spring 2015: Impact wrench for orthopedics

- Fall 2014: Impact wrench for orthopedics

- Spring 2014: Impact Wrench for Orthopedics

- Fall 2013: Impact wrench for orthopedics