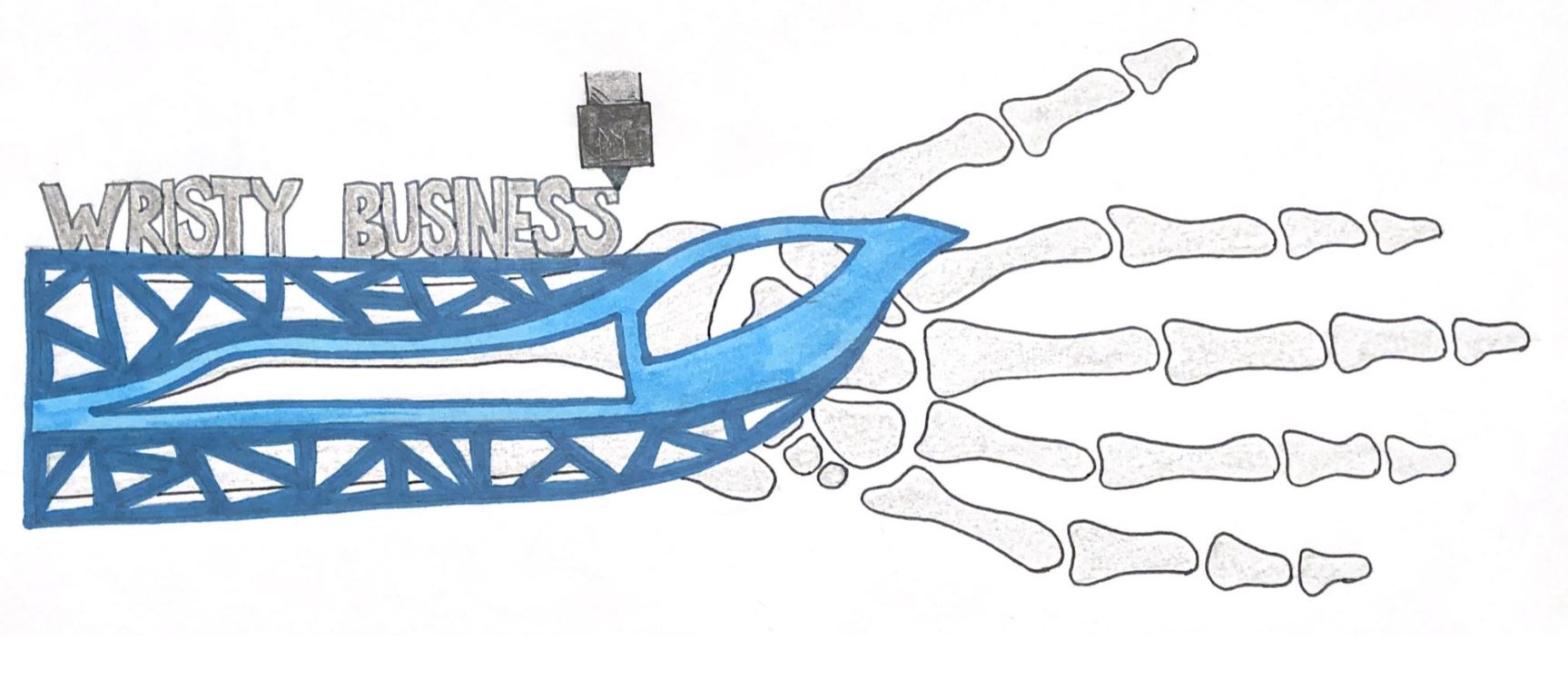

xDI: Rapid liquid 3D printing of patient specific wrist orthoses

This project has been secured to protect intellectual property.

Login for More InformationRetrofitting a 3D printer with Rapid Liquid Printing technology to print wrist orthoses

Project Overview

When a patient requires a wrist orthosis to support weakness or correct maladjustments, the orthopedic surgeon should not be limited by the availability of a hand specialist, the lengthy time it takes to mold the custom orthotic, and the lofty expenses that are often incurred due to these barriers. Current custom wrist orthotics are molded from thermoplastic and can only be conducted by a hand specialist; someone not all hospitals have readily available [1]. Therefore, the Wristy Business team aims to retrofit a readily available 3D printer with Rapid Liquid Printing technology. In the past, 3D printing has been limited by its slow printing time [1]. However, Rapid Liquid Printing prints into a viscous paste that allows for more material to be ejected at a time, thus greatly reducing the printing time [2]. This revolutionary technology would increase the range of material options and eliminate the need for a specialist to mold the orthoses. Not only would it be a cheaper alternative, but the quick speed would allow more patients to be treated by a more diverse span of medical professionals.

Team Picture

Image

Contact Information

Team Members

- Cate Fitzgerald - Team Leader & Communicator

- Benjamin Armstrong - Co-BSAC

- Gabrielle Snyder - Co-BSAC & BPAG

- George Halunen - Co-BSAC

- Emma Neumann - BWIG

- Tyler Dorobek

Advisor and Client

- David Piotrowski - Advisor

- Dr. Zachary French - Client

- Matt Hudson - Alternate Contact

Related Projects

- Spring 2026: Rapid liquid 3D printing of patient specific wrist orthoses

- Fall 2025: Rapid liquid 3D printing of patient specific wrist orthoses

- Spring 2025: xDI: Rapid liquid 3D printing of patient specific wrist orthoses

- Fall 2024: xDI: Rapid liquid 3D printing of patient specific wrist orthoses

- Spring 2024: xDI: Rapid liquid 3D printing of patient specific wrist orthoses

- Fall 2023: xDI: Rapid liquid 3D printing of patient specific wrist orthoses

- Spring 2023: xDI: Rapid liquid 3D printing of patient specific wrist orthoses

- Fall 2022: xDI: Rapid liquid 3D printing of patient specific wrist orthoses

- Spring 2022: xDI: Rapid liquid 3D printing of patient specific wrist orthoses

- Fall 2021: xDI: Rapid liquid 3D printing of patient specific wrist orthoses