Generation of an accessible and versatile hypoxia chamber

Project Overview

ABSTRACT

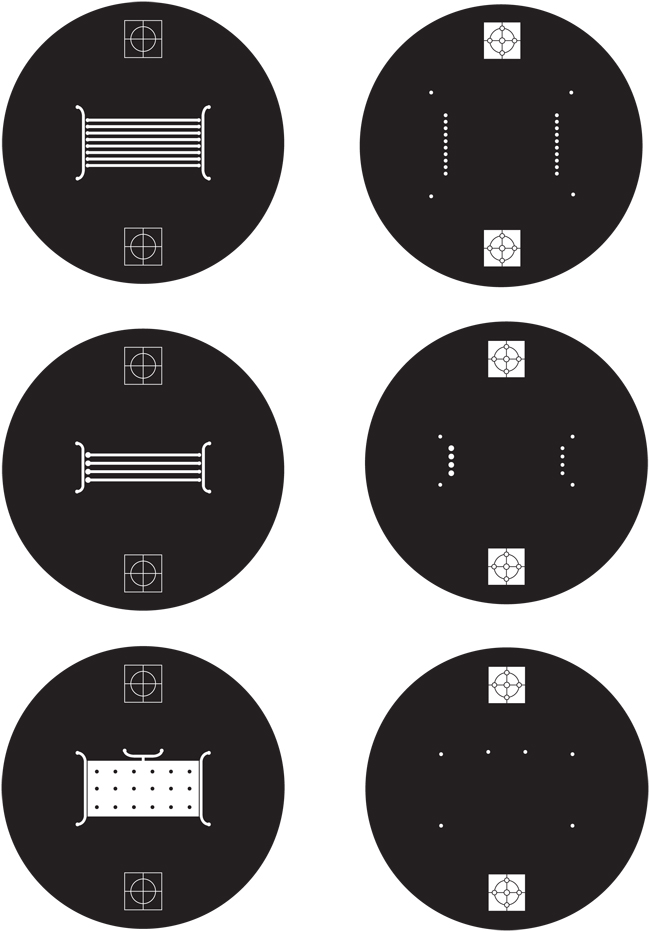

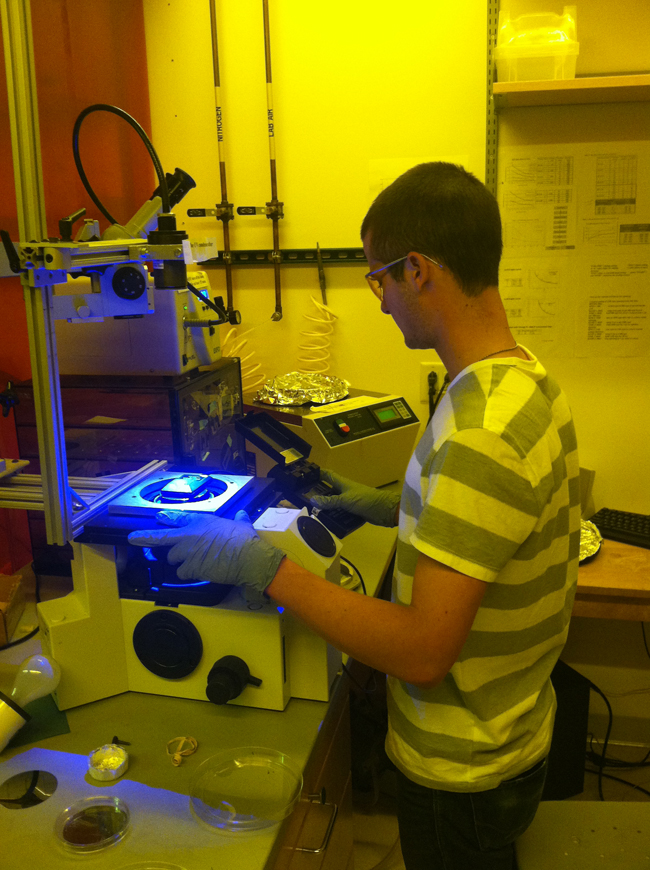

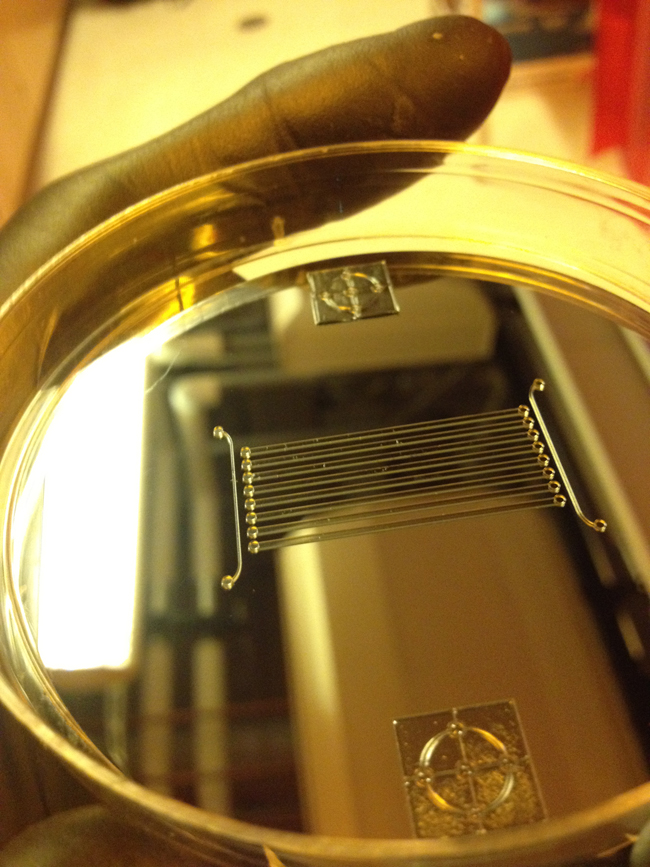

Myocardial infarctions, more commonly known as heart attacks, are responsible for one in four American deaths. Ischemia, which is the term for lack of sufficient oxygen supply to cells, leads to cardiac cell apoptosis in the heart. Heart cells are terminally differentiated, so in the event of a mass apoptotic event, the heart is severely weakened. Current cardiac research is focused on grafting mesenchymal stem cells (MSC) to ischemic heart cells to cause fusion and induce the production of new heart cells. It is hypothesized that MSCs are more likely to fuse with cardiac cells under hypoxic conditions, which is an environment in which cells are under stress due to an oxygen deficiency. The goal of this project is to develop a microfluidicbased hypoxia chamber to facilitate studies involving oxidative stress, ischemia, and reactive oxygen species (ROS) in mediated cellular pathways. In designing the device platform, two main components were considered: microfluidic channel design and oxygen sensing techniques. The combination of fine gas control and oxygen sensing techniques with a microfluidic system will simulate an in vivo environment more closely than previous methods.

Team Picture

Images

Files

- Final Paper (May 9, 2012)

- Mid-semester Presentation (March 14, 2012)

- Mid-semester Paper (March 14, 2012)

- Poster (May 7, 2012)

- Product Design Specifications (May 9, 2012)

Contact Information

Team Members

- Bradley Wendorff - Team Leader

- Drew Birrenkott - Communicator

- Jared Ness - BSAC

- Caleb Durante - BWIG

Advisor and Client

- Prof. Tracy Jane Puccinelli - Advisor

- Prof. Brenda Ogle - Client

Related Projects

- Spring 2013: Generation of an accessible and versatile hypoxia chamber

- Fall 2012: Generation of an accessible and versatile hypoxia chamber

- Spring 2012: Generation of an accessible and versatile hypoxia chamber