Prostate Cutting Device

Project Overview

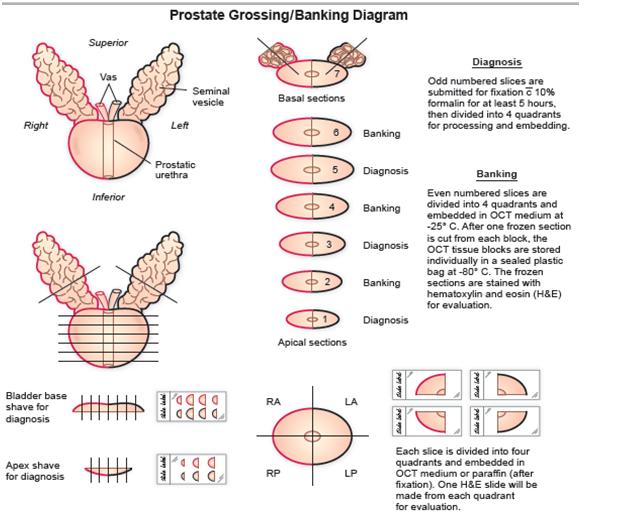

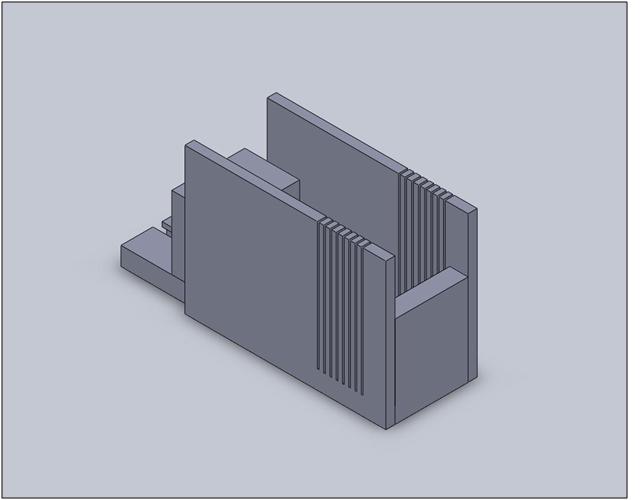

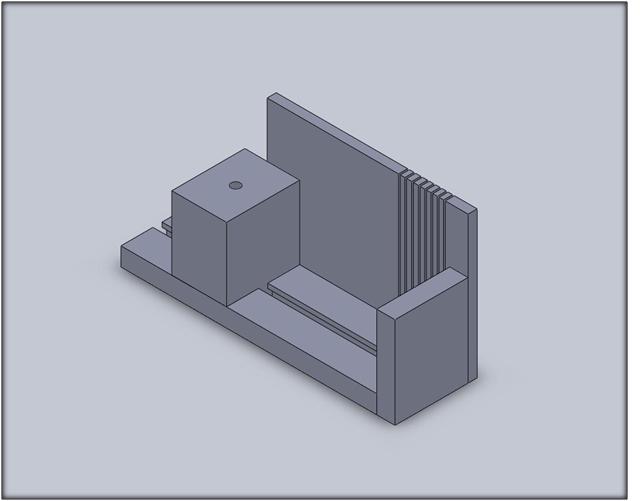

Prostate cancer affects 1 out of 6 men in the United States. A normal prostate weighs 20-30g, while a diseased prostate can weigh up to 100 grams. In order to properly diagnose this cancer, a biopsy must be performed on a dissected prostate sample. Our client would like us to fabricate a device that secures the prostate while the pathologist slices 3mm segments. This device should contain a measurement grid that allows the pathologist to easily dissect the prostate into the 3mm segments and should be adjustable to accommodate varying prostate sizes. Eventually, our device could be used to cut and examine tissues other than the prostate.

Team Picture

Images

Files

- Product Design Specifications (February 12, 2010)

- Mid-Semester Presentation (May 14, 2010)

- Poster (April 30, 2010)

- Final Paper (May 5, 2010)

Contact Information

Team Members

- John Cheadle - Co-Team Leader

- Rebecca Clayman - Co-Team Leader

- Terra Gahlman - Communicator

- Katie Pollock - BSAC

- Kimberly Safarik - BWIG

Advisor and Client

- Dr. Willis Tompkins - Advisor

- Wei Huang - Client