Reducing whole-body vibrations on neonatal transport

Develop an accesory device that reduces whole-body vibrations during neonatal transport.

Project Overview

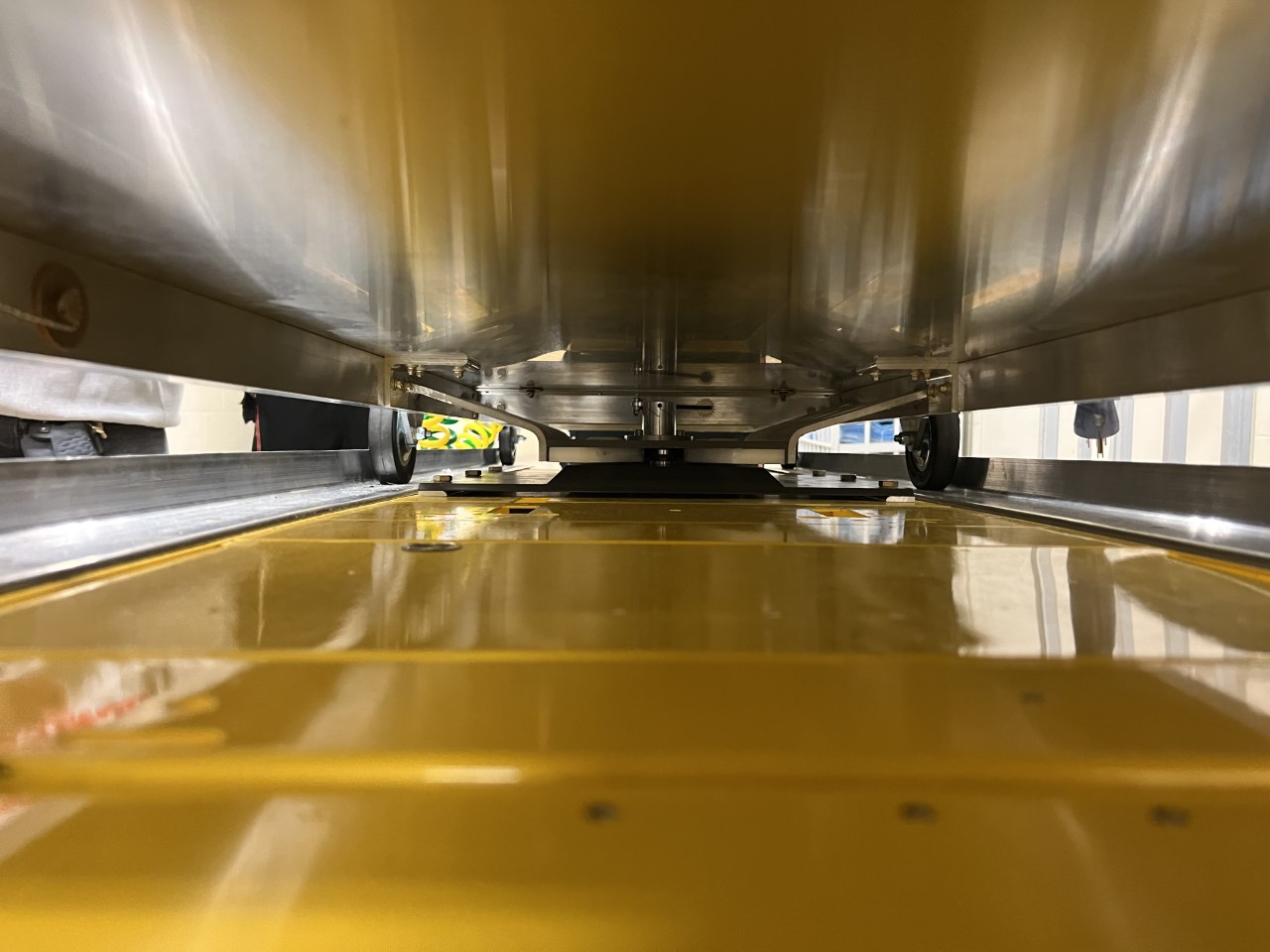

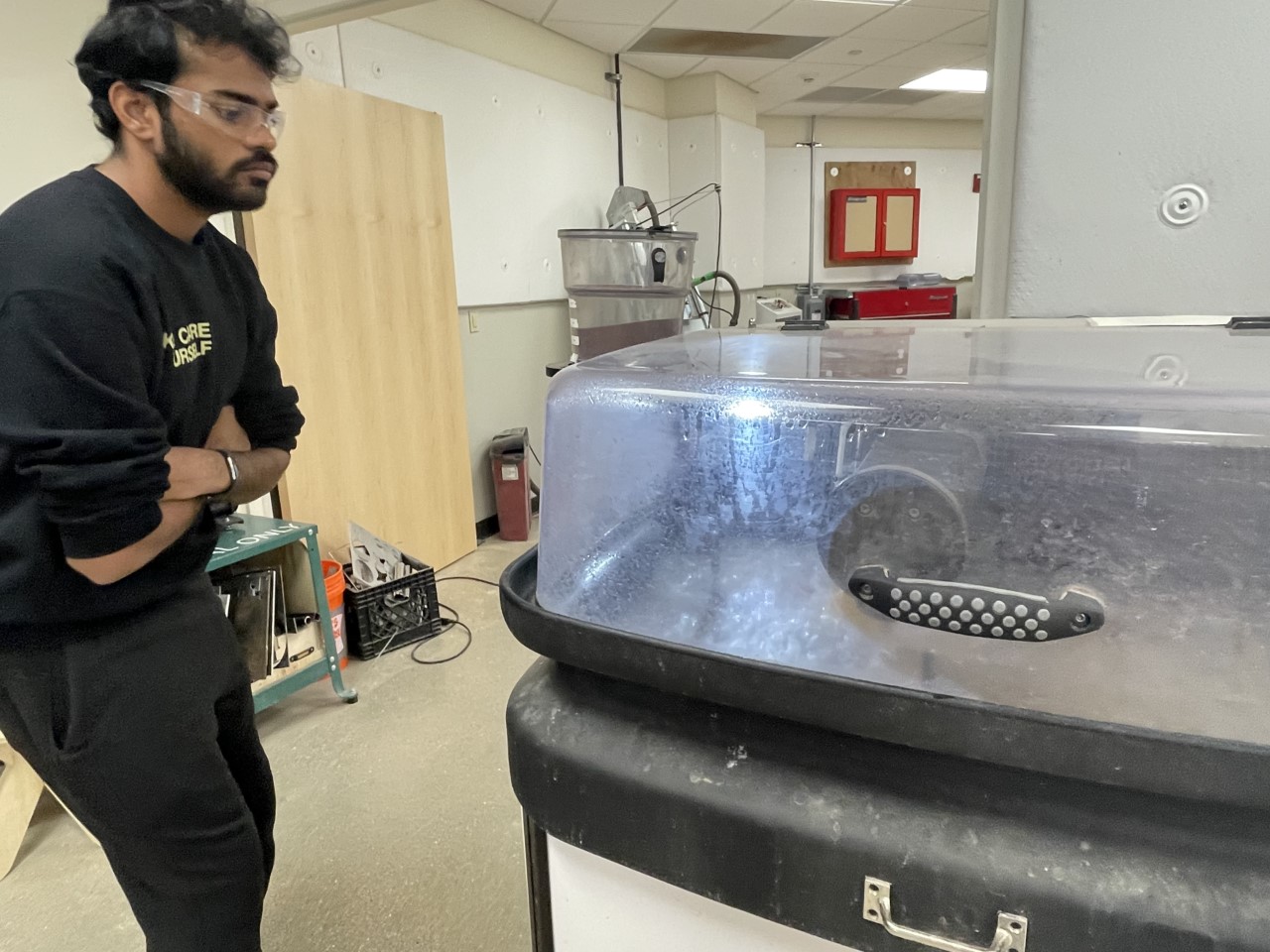

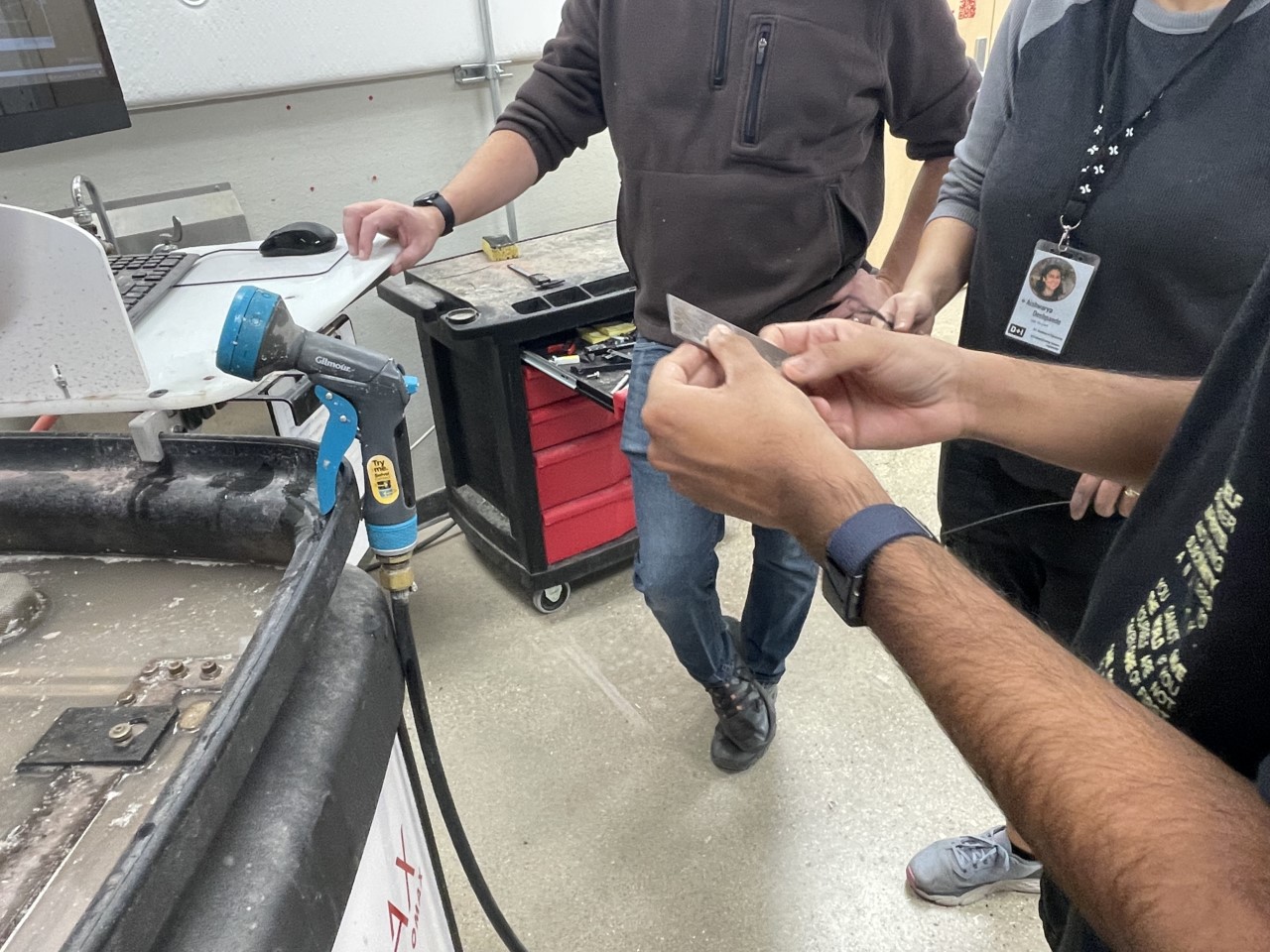

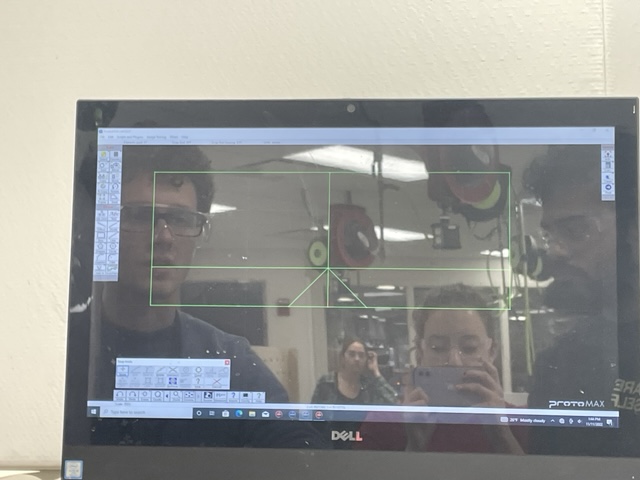

Critically ill neonates as a result of birth defects or other disorders require transport to neonatal intensive care units (NICU) where specialized medical professionals and equipment increase their chances of survival. Transport in ambulances or helicopters, while necessary, induces physiological stressors which adversely affect the health of the neonates. In particular, whole body vibration (WBV) and excessive sound levels can induce head bleeds, leading to subsequent neurodevelopmental impairment or death. Minimizing the effects of mechanical vibrations and rotational and translational motion could improve outcomes during transport. The current transport incubator has ventilators, monitoring equipment, and temperature control mechanisms, but no control of the physical stressors aforementioned. The client, Dr. Ryan McAdams, has tasked the team with developing a novel transport bed to minimize these issues. The new bed must ensure the safety and security of the neonate while maintaining the functions of current incubators.

Team Picture

Images

Files

- Final Report (December 15, 2022)

- Images and Videos (December 15, 2022)

- Final Notebook (December 15, 2022)

- Final Poster Presentation (December 9, 2022)

- Preliminary Report (October 12, 2022)

- Preliminary Presentation (October 7, 2022)

- PDS (September 23, 2022)

Contact Information

Team Members

- Joshua Varghese - Team Leader

- Sydney Therien - Communicator

- Greta Scheidt - BSAC

- Julia Salita - Co-BWIG

- Neha Kulkarni - Co-BWIG

- Joseph Byrne III - BPAG

Advisor and Client

- Prof. Justin Williams - Advisor

- Dr. Ryan McAdams - Client

Related Projects

- Spring 2024: Reducing whole-body vibrations on neonatal transport

- Fall 2023: Reducing whole-body vibrations on neonatal transport

- Spring 2023: Reducing whole-body vibrations on neonatal transport

- Fall 2022: Reducing whole-body vibrations on neonatal transport